When a J1939 cable assembly fails in a modern combine or self-propelled sprayer, it’s rarely a clean break. The failure emerges from two relentless, synergistic forces: low-frequency, high-amplitude vibration that mechanically fatigues every connection point, and a corrosive chemical cocktail that infiltrates every microscopic opening. The symptom is never convenient—it’s the intermittent fault code that appears only at peak operational load, or the elusive “ghost” CAN bus error that disappears in the maintenance bay, only to leave machinery stranded at the field’s far edge. The true cost extends beyond component replacement to downtime during the season’s narrowest harvest windows.

Addressing this challenge requires moving beyond generic “heavy-duty” catalog claims. It demands a forensic, engineering-led methodology for specifying the physical layer of your equipment’s data nervous system. The protocol outlined below derives from systematic analysis of hundreds of failed agricultural harnesses.

The Battlefield: A Diagnostic Map of Synergistic Attack

Agricultural machinery doesn’t experience singular failure modes; it undergoes predictable failure cascades. Accurate diagnosis requires understanding how each environmental threat leaves distinctive forensic signatures.

1. Vibration: The Fatigue Initiator (Leads to Increased Resistance)

Forget standardized laboratory sine waves. Farm vibration profiles are random, multi-axis, and shock-loaded. The characteristic 3-8 Hz resonance of a chassis traversing tilled soil finds and amplifies stress concentrations within a harness. Its signature manifests as work-hardening of copper conductors and cracking of brittle intermetallic compounds in soldered joints. This doesn’t create immediate open circuits; instead, it establishes pathways of increased electrical resistance at termination points, detectable only through sensitive milliohm-meter testing during active vibration cycles.

2. The Chemical Arsenal: The Corrosion Accelerant (Leads to Shorts & Signal Degradation)

Agricultural washdown utilizes not pure water but a conductive electrolyte laden with aggressive residues:

- Glyphosate & Herbicides: Their surfactant systems and carrier agents are engineered for penetration. Their forensic signature includes plasticization of standard PVC or rubber jacketing, transforming it into a soft, tacky material prone to tearing and abrasion.

- Liquid Fertilizer (e.g., UAN – Urea Ammonium Nitrate): These highly hygroscopic compounds form persistent, corrosive films. Their signature appears as white crystalline deposits (potassium/ammonium chlorides) inside connector cavities and causes hydrolytic degradation of polyurethane jacketing.

- Manure Slurry: This biological medium produces organic acids and hydrogen sulfide. Its signature involves sulfuric acid formation leading to rapid copper sulfide corrosion on cable shields and electrical contacts.

- To build a truly effective defense, you must move beyond generic chemical categories and develop a precise “Chemical Threat Dossier.” Our guide on Agricultural J1939 Cable Solutions details how to use Safety Data Sheets (SDS) for threat assessment and material compatibility matching to prevent catastrophic failure.

3. The Synergy: The Failure Cascade

Vibration doesn’t merely coincide with chemical attack; it actively enables it. Vibration performs two critical preparatory functions: First, it mechanically abrades micro-thin protective platings on contacts. Second, it causes permanent set in elastomeric seals, creating a capillary pathway at the seal-to-wire interface (typically at the 6 o’clock position). Chemical washdown then preferentially migrates to these activated zones. What begins as a minor mechanical flaw (such as a 5% increase in crimp resistance) transforms into an active electrochemical corrosion cell, accelerating failure rates by an order of magnitude compared to any single-factor laboratory test.This accelerated failure from synergistic stress is a common challenge in harsh environments. As documented in our Forensic Guide to Refrigerated Transport Wiring Harness Failure, extreme thermal cycling synergizes with vibration to pump moisture into connectors, creating elusive intermittent faults.

The Root Cause: A Forensic Examination of Interface Failures

J1939 cable assemblies consistently fail at their interfaces. Our systematic teardown analysis identifies three universal points of compromise.

1. The Termination Point (#1 Failure Site: High-Resistance Opens)

This is where the battle against vibration-induced fatigue is decided. A soldered termination constitutes a rigid, brittle zone of intermetallic compounds. Under cyclic agricultural stress, these compounds develop micro-cracks, leading to increased resistance and eventual open circuits. The solution rests on a foundational physical principle: a high-integrity, gas-tight crimp. As detailed in our technical analysis on cold weld vibration arbitration, a properly executed crimp forms a cold-weld metallurgical union, allowing the termination to flex as a monolithic metal structure, inherently immune to fatigue failure mechanisms.

2. The Seal-to-Wire Interface (The Primary Wicking Pathway)

Seals are engineered for ideal, smooth jacket surfaces. Field reality involves jackets compromised by over-tightened tie-wraps or chemically degraded materials. The seal loses compressive force, establishing a capillary wicking path. Our forensic teardown database consistently demonstrates that physical or chemical jacket degradation precedes terminal moisture ingress in over 90% of field failures.

3. The Pin-to-Socket Interface: Synergy Culmination Point (Corrosion & High Resistance)

This represents the cascade endpoint. Consider Lab Sample FA-AG23-089 (extracted from a combine main trunk harness): Fretting motion from vibration abraded through the thin tin plating on a pin. Urea-rich moisture established a galvanic cell with the underlying copper alloy substrate. The result was severe fretting corrosion coupled with copper sulfate crystal growth within the connector cavity. Contact resistance escalated from a nominal 2 milliohms to over 500 milliohms—a value more than sufficient to corrupt J1939 data packet integrity and induce the intermittent CAN bus failures our diagnostic guide helps isolate.

Building a Solution: A Step-by-Step Engineering Protocol

Reliability cannot be simply purchased; it must be specified through a documented engineering process.

Step 1: Define the Application Environmental Profile

Before material selection, quantitatively define the operational “battlefield.” This checklist transforms subjective requirements into objectively validatable specifications.

| Location on Machine | Primary Threat | Secondary Threat | Temperature Range | Validation Benchmark |

| Engine Bay (ECU to firewall) | High Temp, Diesel & Oil Vapor | High-Frequency Vibration | -40°C to 125°C | Heat aging per ISO 6722, followed by vibration per MIL-STD-202G, Method 214. |

| Lower Chassis (main harness run) | Mud Immersion, Stone Impact | Abrasion, Hydraulic Oil | -40°C to 105°C | IP67 immersion test (1m, 30 min), followed by abrasion resistance test per DIN 53516. |

| Implement Interface (quick-hitch) | Constant Flexing, Chemical Spray | UV Degradation | -30°C to 90°C | >500,000 cycles on a dynamic flex fixture simulating implement articulation. |

Step 2: Terminate for Mechanical Survival

- Precision Crimp Termination: Mandate controlled-cycle crimping processes, validated through cross-section micrograph analysis and calibrated pull-force testing. This represents the single most critical factor for achieving extended vibration life.

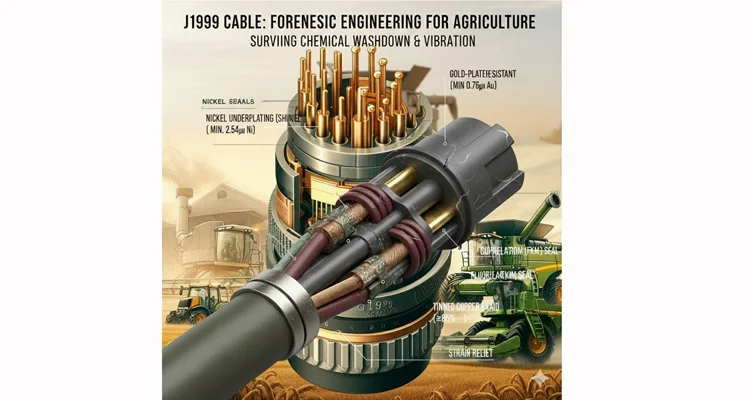

- Integrated Strain Relief: Specify overmolded funnel boot designs that clamp both the cable jacket and shield braid, preventing energy transfer to critical pin/socket areas. Simple clamp-style reliefs are fundamentally inadequate for agricultural duty cycles.

Step 3: Select Materials for Chemical Warfare

- Jacket: Avoid standard PVC formulations. Specify hydrolysis-resistant Thermoplastic Polyurethane (TPU) or Cross-linked Polyethylene (XLPE) compounds. Require material certification demonstrating <10% volume swell after 48-hour immersion in your primary chemical agent (e.g., 10% UAN solution).

- Seals: Utilize Fluoroelastomer (FKM/Viton) for broad-spectrum chemical resistance or specific agricultural-grade EPDM formulations. The seal design must incorporate multi-lip, progressive sealing geometry.

- Contacts: Specify heavy gold-flash over nickel underplating (minimum 0.76µm Au over 2.54µm Ni). The nickel layer serves as the corrosion barrier; gold provides a stable, low-friction conductive surface.

- Material selection requires balancing trade-offs. The unique threat profile of different machine zones (e.g., cabin, chassis, implement) demands a systematic logic. Our analysis, J1939 Cables for Agricultural Machinery: Engineering a Solution, provides a detailed decision framework based on Zone-Based Threat Assessment (ZBTA).

Step 4: Shield and Drain for Signal Integrity

- Shielding: Employ a tinned copper braid (≥85% coverage minimum). The tin coating provides sacrificial protection against internal corrosion should the outer jacket become compromised.

- Termination: Ensure 360-degree shield termination to the connector backshell via a conductive compression gland, establishing a complete Faraday cage. Inadequate shield termination is a primary contributor to EMI-induced communication errors, a phenomenon explored in depth within our guide to CAN bus EMI shielding.

Step 5: Validate with Aggressive, Combined-Environment Testing

ISO 16750-3 establishes a baseline. A rigorous protocol must extend further:

Effective validation must simulate superimposed stresses. As demonstrated in our work on Refrigerated Transport Wiring Challenges, a robust protocol requires continuous “thermal shock-vibration-electrical monitoring” cycles, not just sequential, single-factor tests.

- Combined Environmental Testing: Cycle complete assemblies through defined vibration profiles while intermittently spraying them with a simulated agricultural chemical cocktail.

- Thermal Shock Testing: Validate seal integrity and material functionality across the full operational range, from peak summer operating temperatures to immediate post-washdown cold shock conditions.

This PPAP-aligned validation mindset is integral to our IATF 16949:2016 certified manufacturing process. Your deliverable extends beyond a physical cable to include the complete Production Part Approval Process package—comprising Design Records, Material Certifications, and Process Capability (CPK) studies—that demonstrates reliability analytically before field deployment.

This engineering-led approach to **J1939 cable durability in agriculture** aligns with our comprehensive [agricultural J1939 cable durability engineering guide](https://obd-cable.com/j1939-cable-durability-agriculture-engineering-guide/), which provides extended validation protocols and field data analysis.5 Common & Costly Specification Oversights

1. Prioritizing IP69K Rating Over Material Chemical Compatibility

The IP69K test utilizes clean, hot water. A seal material that degrades upon exposure to glyphosate will fail rapidly in service, regardless of its impressive IP rating against pure water.

2. Selecting Connectors Without Specifying Seal & Plating Grades

A generic Deutsch DT connector with commercial-grade (-20) seals and tin-plated contacts will not survive a full agricultural season. You must explicitly specify AGR/ALG series chemical-resistant seals and gold-plated contact pins.

3. Neglecting Drip Loop Design & Minimum Bend Radius

A cable routed taut from chassis to implement creates a perfect conduit for water ingress toward the connector. Always incorporate a low-point “drip loop” into the harness design. Forced sharp bends guarantee premature failure; in constrained spaces, specify a pre-molded 90-degree right-angle J1939 cable.

4. Over-Tightening Zip Ties or Utilizing Inadequate Clamps

A cinched plastic tie creates a guaranteed stress concentration riser that will mechanically cut through the jacket under persistent vibration. Transition to cushioned clamping systems or protective loom tubing.

5. Treating the Harness as a Commodity Component

Conduct a rigorous Total Cost of Ownership (TCO) analysis. The comprehensive cost of a single field failure during harvest—factoring in downtime, emergency labor, and lost yield—typically dwarfs the upfront investment in a properly engineered, application-specific harness.

Verification Protocol: Confirming Your Solution is Engineered to Last

Robust validation should precede installation. A trustworthy solution provides:

Documentation: The Comprehensive PPAP Dossier

A Complete PPAP Folder from your supplier, including Design Records, Material Certifications (with empirical chemical resistance data), and Process Capability (CPK) studies for the crimping process (CPK >1.67 represents the automotive industry standard for a robust, controlled process).

Testing: Relevant & Aggressively Sourced Data

The test report must specify verifiable results, e.g., *”Passed 300 hours of SAE J1455 random vibration profile, followed by 24-hour immersion in 10% glyphosate solution, with zero electrical discontinuities exceeding 1 microsecond.”*

Design: Purposeful, Service-Centric Architecture

The harness design must incorporate service loops, proper clamping at recommended intervals (e.g., 300mm), and routing that systematically avoids identified abrasion points and heat sources.

Engineered Components for Specific Field Applications

Reliability is not one-size-fits-all. Below are targeted solutions for common integration challenges.

For Non-Invasive Diagnostic Access & Tapping

A J1939 9-pin pigtail breakout cable provides a sealed, electrically reliable tap into the CAN bus backbone without compromising the integrity of the main harness through cutting or splicing.

For Cramped Engine Compartments & Tight Bends

A pre-molded J1939 90-degree right-angle cable eliminates the sharp, destructive bend radius that inevitably cracks standard cable jackets and fatigues conductors in confined spaces.

For Legacy Fleet Diagnostics & Protocol Integration

A properly engineered Cummins J1708 to J1939 diagnostic cable ensures full electrical and protocol layer compatibility, preventing the communication errors and network conflicts common with simplistic passive adapters.

Ultimately, most demanding agricultural applications necessitate a custom cable assembly. This involves selecting the exact jacket compound, calculating the correct conductor gauge to manage voltage drop over extended runs, and designing application-specific overmolded strain reliefs for unique mounting points. This transition from standard to custom is where deep engineering collaboration and a certified quality management system—underpinned by IATF 16949, ISO 9001, and ISO 14001:2015—evolve from abstract certificates into tangible reliability advantages.

FAQ: Addressing Critical Engineering Queries

On Material Selection & Chemical Resistance

This is not recommended. Conformal coating can fracture under vibrational stress, trapping moisture underneath and accelerating localized corrosion. It also renders future service or connector replacement exceedingly difficult. Effective, durable sealing must be designed into the connector system from the outset.

No. The chemical exposure profile of a dairy operation (ammonia, organic acids) differs fundamentally from a row-crop enterprise (herbicides, fertilizers). While TPU represents an excellent broad-spectrum option, the specific polymer formulation is critical. We perform a cross-referential analysis of your chemical Safety Data Sheets (SDS) against our proprietary material library to specify the optimal grade for your environment.

On Field Diagnostics & Service Life Expectations

Execute a structured diagnostic hierarchy:

- Visual Inspection for jacket damage, abrasion, and seal integrity.

- With the cable disconnected at both ends, measure the resistance between CAN_H and CAN_L. It should read a stable ~60 ohms (reflecting the two parallel 120-ohm network terminators).

- During measurement, manipulate the harness—particularly at connectors and bends. Any fluctuation in resistance indicates an intermittent fault location. Our dedicated failure analysis guide provides a comprehensive diagnostic flowchart.

Frame expectations accurately: The core electrical integrity (conductors, crimps) should be designed to match or exceed the machine’s major overhaul interval—typically 8,000-10,000 engine hours for high-utilization equipment. However, the external barrier system (jacket, seals) functions as a consumable. Based on aggregated fleet data, we advocate for a planned inspection and seal service interval at 2,500-hour marks, transforming unpredictable random failures into managed, scheduled maintenance events.

On Quality Systems & Design-Phase Collaboration

It institutionalizes process control and full traceability, moving beyond a simple product certificate. It ensures every material batch is documented, every crimp is validated against a force-displacement curve, and any process deviation triggers a systemic root cause analysis. This system is architected to prevent defects proactively, a philosophy central to our zero-defect cable process.

Engagement at the concept routing stage is ideal. Sharing initial CAD models or sketches of the machine frame and ECU locations enables our engineers to advise on optimal harness routing, minimum bend radii, clamp placement strategies, and connector orientation before the design is frozen, preventing costly and reliability-compromising modifications later in the development cycle.

Engineering Support & Project Initiation

Specifying a cable system that endures the agricultural environment is an engineering challenge, not a routine procurement task. It necessitates a partner with a forensic understanding of the underlying failure chemistry and physics.

If you are drafting a new design specification or require a harness upgrade predicated on a failure mode and effects analysis (FMEA), our engineering team can apply this forensic protocol to your specific operational challenge.

Discuss Your Specific Application (WhatsApp): +86 17307168662. Share photographs of the installation environment, a routing sketch, or the MSDS sheet for your primary chemicals for a preliminary compatibility and design assessment.

Request a Formal Specification Review (Contact Page): For detailed OEM customization questionnaires or to formally initiate a PPAP project, please submit your requirements via our contact form. We will respond with a tailored Harness Design Specification document for your machine model.