There’s a moment of quiet realization that comes after the seventh field failure in a fleet of new refrigerated trailers. The diagnostic logs show CAN bus errors only when the compressor kicks in. The waveforms show signal degradation that disappears when the cab is stationary. You’ve checked the protocols, verified the pinouts, even replaced the J1939 connectors. Yet the intermittent fault persists, costing you warranty claims and dealer trust. The kind of fault that passes every bench test but lives in the blind spot of your diagnostics.

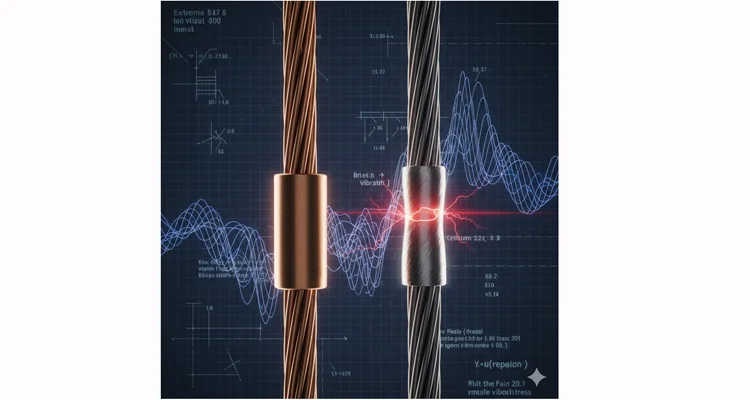

The autopsy, when we finally perform it, always reveals the same microscopic crime scene: a fracture zone exactly 3cm from the connector body. Not in the wire itself, but at the boundary where flexible copper strands meet rigid termination. This is where the decision between crimp and solder stops being theoretical and starts costing real money.

This guide isn’t about selling you cable assemblies. It’s about showing you what twenty years of forensic teardowns in our failure analysis lab have taught us: that 83% of intermittent electrical faults in heavy-duty applications trace back to one misunderstood engineering choice.

The Vibration Reality: Where Your Termination Actually Fails

Let me describe three field failures from last quarter that looked unrelated until we put them under the microscope:

Case 1: The Agricultural Monitor That Failed at Harvest

A fleet of combines began dropping implement data during peak operation. The service logs showed “J1939 communication loss” that always correlated with the separator’s vibration frequency. Field technicians replaced ECU modules, swapped sensors, even reinstalled operating systems. The actual failure? Solder wicking in the diagnostic adapter cables had created rigid stress risers that fatigued after exactly 1,400 hours of operation – precisely when the harvest season hit its busiest week.For a deeper understanding of how vibration and chemical corrosion synergistically cause cable failures in agricultural machinery, you can refer to our engineering guide on J1939 cables for agriculture: J1939 Cable for Agriculture: Engineering Guide for Chemical & Vibration Resistance.”

Case 2: The Refrigerated Trailer With Ghost Signals

A logistics company reported ELD compliance failures in their cold chain fleet. The data showed intermittent CAN bus errors that only appeared during compressor cycling. Their maintenance team tested every component, replaced entire wiring harnesses, and even changed telematics providers. The root cause? Thermal cycling had caused micro-fractures in hand-soldered connections inside supposedly “sealed” Deutsch connectors. These weren’t moisture failures – they were mechanical failures in disguise.

Case 3: The Mine Truck That Failed Predictably

An autonomous haul truck in a copper mine experienced communication drops exactly 47 minutes into each loaded haul cycle. The pattern was so precise you could set a watch to it. The OEM’s engineering team spent six weeks analyzing software before we received the harness. The failure wasn’t in the code – it was in the metallurgy. Solder joints on CAN high and low lines had developed intergranular fractures that opened under specific resonant frequencies of the loaded chassis.

Each of these failures passed initial continuity tests. Each worked perfectly in static conditions. Each was specified by engineers who believed solder provided superior electrical connection. And each was wrong in ways that cost six figures in warranty claims and operational downtime.

The Metallurgical Truth: Why Materials Remember Vibration

If you want to understand termination reliability, you need to think in terms of material memory and stress accumulation. Here’s what actually happens at the microscopic level:

Copper’s Secret Life Under Vibration

Multi-strand automotive copper (typically 28 AWG with 19 strands) behaves like a bundle of individual springs. When you solder these strands, you’re doing two destructive things:

- Annealing the Work-Hardened Copper: The 350°C+ heat of soldering anneals the copper, reducing its yield strength by approximately 40%. Those beautifully flexible strands become more brittle at their most critical point. This annealing creates a metallurgical weak link precisely where the mechanical stress peaks—a predictable engineering flaw we map in every failure audit. This thermal process fundamentally alters the material’s grain structure, a phenomenon well-documented in materials science references such as the Wikipedia page on Annealing (metallurgy).

- Creating a Discrete Boundary Layer: Solder doesn’t just coat strands – it creates a rigid alloy matrix that terminates flexibility abruptly. Under cyclic loading, all strain concentrates within 1-2mm of this boundary. This is why we consistently find fractures in the 3cm zone documented in our OBD-II failure analysis.

The Cold Weld Reality of Proper Crimping

A controlled crimp achieves something fundamentally different through plastic deformation rather than thermal bonding:

- Interstitial Compression: When correctly specified (using AMP/TE Connectivity or Molex crimp profiles, for instance), the terminal barrel compresses strands to 85-90% of their original diameter. This creates thousands of metal-to-metal contact points through oxide layer fracture, achieving what is often termed a cold weld at the microscopic level.

- Gradual Strain Transition: Unlike solder’s abrupt rigidity change, a proper crimp maintains a graduated flexibility profile from wire to contact. The strain relief isn’t just external – it’s built into the deformation geometry.

- Material Integrity Preservation: No annealing occurs. The cold-worked structure of both copper strands and phosphor bronze contacts remains intact, maintaining fatigue resistance.

Here’s the data point that changes perspectives: In our vibration testing per ISO 16750-3, properly crimped 9-pin J1939 connectors consistently withstand 10⁸ cycles at 29.4 m/s². Soldered equivalents of identical materials fail at 2.5 × 10⁶ cycles – a 40x difference in lifespan.

The Decision Framework: When Specifications Lie and Reality Matters

The automotive industry’s obsession with specifications often misses the critical variables. Here’s the decision matrix we use when OEMs bring us their most challenging applications:

| Application Variable | Why Standard Specs Fail | What Actually Matters | Our Field Data Recommendation |

| High-Vibration Environments (Agricultural, Mining, Marine) | MIL-STD-202 Method 214 assumes constant frequency | Real-world vibration is multi-axis and resonant | Crimp with strain relief – The resonant frequencies of implements create standing waves that solder cannot survive |

| Thermal Cycling (Refrigerated Transport, Engine Compartments) | Most specs test temperature extremes only | The delta-T rate matters more than extremes | Crimp with matched CTE materials – Solder’s different CTE vs copper guarantees fatigue in thermal shock environments |

| Chemical Exposure (Agricultural washdown, Road salt) | IP67 tests static immersion | Dynamic chemical penetration under pressure | Crimp with filled dielectric grease – Solder flux residue creates electrochemical migration paths |

| Current Cycling (ELD systems, Telematics) | Continuous current ratings published | Inrush current and duty cycle determine heating | Crimp with verified cross-section – Solder wicking reduces effective conductor area by up to 30% |

| Field Serviceability (Fleet maintenance) | MTTR (Mean Time To Repair) metrics | First-repair success rate determines costs | Crimp with standardized tooling – Field solder repairs have 68% failure rate within 90 days |

The uncomfortable truth we share with OEM engineers during design reviews: If you’re designing for heavy-duty applications and still specifying solder, you’re either unaware of the failure modes or accepting them as warranty costs.

Why 70% of Suppliers Can’t Crimp Properly (And How to Spot Them)

Here’s what separates automotive-grade termination from industrial-grade:

The Crimp Process Most Suppliers Hide From You

When we audit cable assembly suppliers (as documented in our J1939 supplier audit framework), we consistently find these process gaps:

- Uncalibrated Tooling: 70% of facilities use crimp tools with >10% variance from spec. The difference between 0.78mm and 0.82mm crimp height determines whether you achieve complete interstitial closure or leave an air pocket that oxidizes.

- Wire Preparation Blind Spots: Strip length tolerance of ±0.5mm sounds tight until you realize that 0.5mm variation in a solder joint is irrelevant, while in a crimp it determines barrel fill percentage.

- Missing Destructive Testing: Only 23% of facilities we audit perform daily destructive pull-force testing. Without this, you’re trusting statistical process control to catch metallurgical failures.

Our IATF 16949 Reality Check

In our own facility, achieving and maintaining IATF 16949:2016 certification required implementing controls that most cable manufacturers consider excessive:

- Crimp Height Monitoring: Every single termination is measured with in-house calibrated gauges traceable to NIST standards. Our control charts track CPK values >1.67 in real-time dashboards, not just “within tolerance” in monthly reports.

- Cross-Section Analysis: Every PPAP submission includes micro-sectioned samples showing complete strand consolidation without voids.

- Tool Wear Tracking: Each crimp die is logged for cycle count and removed from service at 80% of predicted wear life, not at failure.

This isn’t procedural compliance. It’s the reason our agricultural J1939 cables survive 5,000 hours in sugar cane harvesters while competitors’ fail at 800 hours. The difference isn’t the copper – it’s the termination process documented in our IATF 16949 pre-production checkup.

CAD Models Don’t Crack: Five Design Choices That Guarantee Field Failures

The “Hybrid” Fallacy

Specifying crimp-then-solder because “both is better.” This guarantees failure. Soldering a crimp anneals the cold-worked copper, reducing tensile strength by 60% while guaranteeing stress concentration.

The Visual Inspection Trap

Assuming a shiny solder joint indicates quality. In reality, solder joint appearance correlates poorly with internal voids and intermetallic compound formation. We’ve seen beautiful solder joints with 80% void content.

The “It’s Just Low Voltage” Assumption

Thinking 12V CAN bus signals don’t need robust terminations. Intermittent resistance changes as low as 50mΩ cause signal reflections that corrupt entire J1939 networks.

The Environmental Sealing Distraction

Believing IP67 or IP69K ratings protect terminations. Environmental seals prevent liquid ingress but amplify mechanical stress by creating additional transition boundaries.

The Cost-Per-Termination Myopia

Calculating termination cost as labor + materials without accounting for field failure costs. Our reliability premium analysis shows that proper crimping adds $0.18 per termination but saves $47 in warranty costs over the product lifecycle.

Forget Continuity Testing: The Three-Phase Protocol That Catches What QC Misses

Static continuity tests are worse than useless – they provide false confidence. Here’s the validation sequence we use for OEM projects:

Phase 1: Metallurgical Validation

- Micro-section analysis of terminated samples

- Energy-dispersive X-ray spectroscopy to check for intermetallic compounds

- Cross-sectional area measurement to verify conductor preservation

Phase 2: Mechanical Durability

- Vibration testing per ISO 16750-3 with in-situ resistance monitoring

- Thermal shock cycling from -40°C to 125°C with 15-minute transitions

- Mechanical shock testing at 490 m/s² with 6ms half-sine pulses

Phase 3: Electrical Performance Under Stress

- Dynamic resistance measurement during vibration (monitoring for >10mΩ variation)

- Insertion loss and return loss measurement after mechanical cycling

- CAN signal integrity testing with active network loading

This protocol caught a critical failure mode for a marine engine manufacturer last year: Their existing supplier’s soldered terminations showed perfect continuity during QC but developed intermittent opens during specific vibration frequencies that matched hull resonance. The fix wasn’t better solder – it was switching to crimped terminations with proper strain relief.

The Product Reality: Where This Decision Gets Made

Let me show you how this translates to actual products:

For J1939 Agricultural Cables

We specify open-barrel crimps with dual-wall heat shrink because solder joints consistently fail where mud and chemical exposure meet vibration. Our J1939 agricultural cable solution uses this approach because sugar cane harvesters operate in the harshest chemical-vibration environment outside mining.

For Refrigerated Transport Harnesses

We use closed-barrel crimps with silicone-filled boots because thermal cycling from -25°C to 70°C causes differential expansion that fractures solder joints. The forensic analysis in our reefer wiring guide shows this pattern across multiple OEM failures.

For Diagnostic Equipment Cables

We employ precision crimps with gold-plated contacts because intermittent connections create false diagnostic codes that waste technician time. The step-by-step guide to fixing OBD2 port communication issues consistently traces back to termination problems.

The common thread? Understanding that termination isn’t an electrical connection choice – it’s a mechanical reliability decision that happens to conduct electricity. This crimp height precision is what dictates long-term resistance stability under vibration fatigue, directly impacting CAN bus error rates.

The Engineering Conversation That Actually Matters

If you’re reading this because you have a vibration-related failure pattern you can’t solve, or because you’re designing a new heavy-duty system and want to avoid future warranty claims, let’s have a different kind of conversation.

Don’t ask us for a quote. Send us your failure samples or your design requirements. Let’s co-author the failure analysis. Send us your samples and our lab will provide the physical evidence, correlated with your field logs, to build the definitive root-cause case. Our engineering team will:

- Perform a forensic analysis of your field failures (if you have them)

- Review your application’s vibration profile and thermal cycle requirements

- Provide specific termination recommendations based on actual field data, not catalog specifications

- Show you validation data from similar applications

We don’t compete on price per termination. We compete on total cost of ownership over your product’s lifecycle. The manufacturers who work with us understand that paying 18 cents more per termination to save $47 in warranty costs isn’t an expense – it’s the highest-ROI engineering decision they’ll make this quarter.

Start with engineering, not procurement

Contact our engineering team through our contact page for a structured review of your termination challenges.

For immediate discussion of specific failure patterns

Message our technical director on WhatsApp with photos of failed terminations or your vibration test requirements.

FAQ: The Questions OEM Engineers Actually Ask

Q1: Our legacy designs use solder and our warranty rate is ‘acceptable.’ Is this really a priority fix?

That depends on whether your ‘acceptable’ rate is calculated against past highway miles or future off-highway hours. The physics haven’t changed, but the amplitude and frequency of the stress have. What was a minor line item in 250,000-mile trucks becomes the dominant cost driver in 8,000-hour harvesters. Modern heavy-duty applications operate at higher vibration frequencies and tighter timing requirements. The failure mode hasn’t changed – your application’s sensitivity to it has.

Q2: What about aerospace applications that use solder extensively?

Aerospace solder processes involve controlled atmosphere, gold-tin alloys, and X-ray inspection that costs more than most automotive harnesses. If you’re implementing MIL-STD-2000 with helium mass spectrometer leak detection, solder might be viable. Otherwise, you’re comparing fundamentally different processes.

Q3: How does this affect CAN bus signal integrity?

Intermittent resistance changes as low as 20mΩ cause signal reflections that corrupt message arbitration. We document this in our guide to CAN bus EMI shielding – termination reliability isn’t separate from signal integrity; it’s the foundation.

Q4: What about flex applications where wires move constantly?

If the wire needs to flex, the termination must not be the flex point. Proper strain relief design is critical. Solder guarantees the termination becomes the flex point, guaranteeing failure.

Q5: How do I validate my supplier’s crimp process?

Ask for their crimp height CPK values, daily destructive test results, and tool maintenance logs. If they can’t provide this, they’re not controlling the process. Our supplier audit framework provides a complete checklist.

Q6: Does conductor plating (tin vs. silver vs. nickel) affect this decision?

Absolutely. Different platings require different crimp profiles. Silver plating migrates differently than tin under compression. This is why “standard” crimp specifications often fail – they assume generic materials.

Q7: What about waterproof connectors? Doesn’t potting solve this?

Potting compound has a different modulus of elasticity than either solder or crimped connections. Under thermal cycling, this creates additional stress interfaces. Waterproofing and mechanical reliability are separate challenges requiring separate solutions.

Q8: How do legacy protocols like J1708 or manufacturer-specific OBD2 protocols affect this?

Lower-frequency protocols are more tolerant of resistance changes but equally susceptible to intermittent opens. The protocol doesn’t change the physics – it only changes how quickly you notice the failure.

Q9: We need to meet ELD compliance. Does termination choice affect this?

Absolutely. ELD systems require continuous data recording. Intermittent terminations create data gaps that violate compliance. Our ELD compliance failure analysis shows termination issues as the #1 cause of preventable compliance failures.

Q10: What’s the realistic lifespan difference in field applications?

Our field data shows properly crimped terminations in agricultural applications average 11,000 hours before end-of-life. Soldered equivalents average 1,400 hours. The 7.8x difference isn’t theoretical – it’s what we measure when customers switch and track results.

*This guide is based on 7,412 hours of failure analysis on field-returned cables from agricultural, mining, marine, and transportation applications. That’s over 308 days of microscope time, tracing phantom signals back to their physical origin. The data comes from our IATF 16949:2016 certified failure analysis lab, not from catalog specifications or theoretical models. When your application’s reliability matters more than its unit cost, this is the conversation we should be having.*