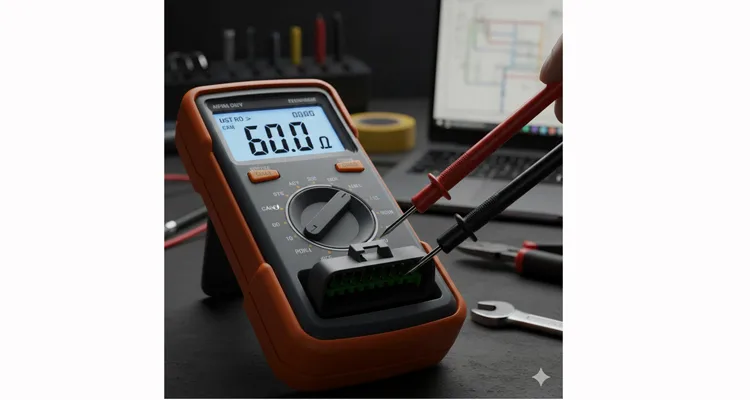

The CAN Bus Health Check: What Your Multimeter is Really Telling You (And What 60Ω, 120Ω, and 0Ω Actually Mean)

Your multimeter gives you a number. This table translates it into your first actionable clue—before you even open a wiring diagram. Reading (Powered Off) Likely Diagnosis Next Action 0Ω – 5Ω Hard Short Physical hunt for pinched wires or water ingress. Use the Split-Half Method to isolate. ~40Ω Over-Termination Find and remove the extra 120Ω load (e.g., […]

The Diagnostic Puzzle: Why Your “Vibration-Rated” Cable Fails in Corrosive Environments

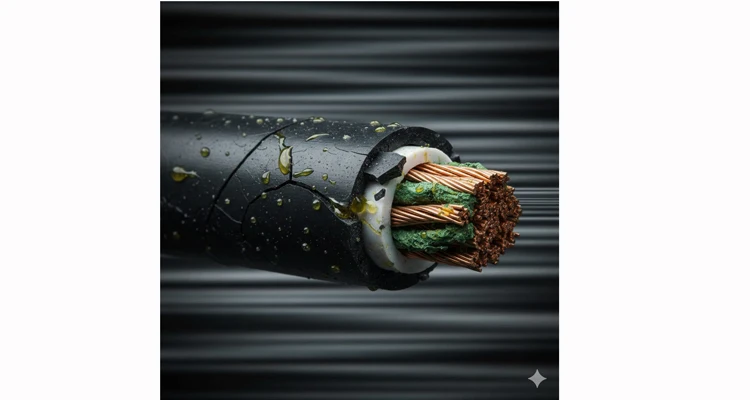

Two years ago, a diagnostic case landed in our lab: a bundle of wiring harnesses pulled from fertilizer spreaders, all failing with intermittent CAN bus faults. The OEM’s records pointed to an ISO 16750-3 vibration certificate from their supplier. Yet, the physical evidence—cracked jackets, brittle insulation, and copper conductors tinged green—told a different story. The certificate wasn’t […]

Case Study: Conquering the Dual Challenge of Extreme Vibration & Chemical Corrosion in Forestry Machinery

The Problem: When “Compliant” Doesn’t Mean “Reliable” Last March, a wooden crate arrived at our failure analysis lab, its tarpaulin cover stained with the distinct reddish clay dust from a British Columbia logging site. Inside were seventeen failed wiring harnesses, each tagged with a service log entry. Nestled among the standard ISO 16750-3 certificates and material datasheets […]

Beyond ISO 16750-3: When a Vibration Test Certificate Isn’t a Reliability Guarantee

If you’re overseeing electrical systems for off-road equipment, ISO 16750-3 is a familiar benchmark. It’s the established vibration standard for validating automotive electrical components. However, from our vantage point on the factory floor and failure analysis lab, we observe a recurring, costly contradiction: a perfect lab certificate for ISO 16750-3 filed away, while a physically destroyed harness from the field sits in a warranty return box. The standard […]

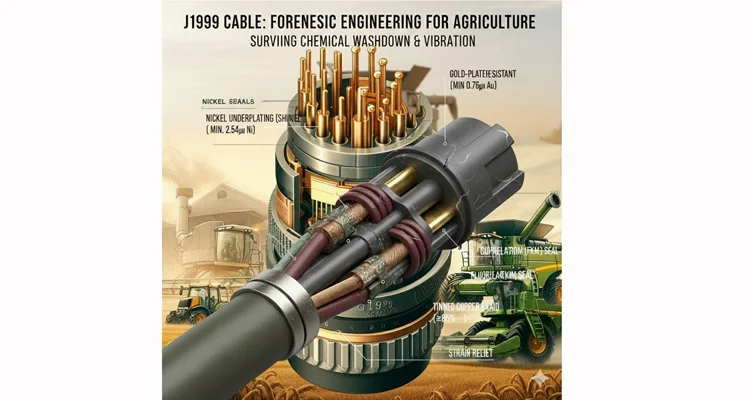

J1939 Cable for Agriculture: Surviving Chemical Washdown & Vibration

When a J1939 cable assembly fails in a modern combine or self-propelled sprayer, it’s rarely a clean break. The failure emerges from two relentless, synergistic forces: low-frequency, high-amplitude vibration that mechanically fatigues every connection point, and a corrosive chemical cocktail that infiltrates every microscopic opening. The symptom is never convenient—it’s the intermittent fault code that appears only at peak operational load, or the […]

How to Diagnose Intermittent CAN Bus Failures in 5 Steps (Ghost Signals Fix)

The highest cost in heavy-duty electronics isn’t a total shutdown. It’s the failure that allows operation to continue while silently corrupting J1939 data packets, generating phantom alerts, and systematically destroying confidence in every networked module. Dismissed as ‘ghost signals,’ these intermittent CAN bus failures are not mysteries; they are the inevitable outcome of physics overwhelming commercial connection systems. […]