Three PDFs land in your inbox. Same J1939 connector pinout drawing. Same delivery terms. The only difference? A 27% spread in unit price. Your procurement team’s favorite question—“Why wouldn’t we take the cheapest?”—is about to cost your project six figures in hidden rework.

I know because I used to ask that question from the OEM engineering side. Now I run the factory that fixes the cables chosen by that logic. That mindset ignores the physics of failure and the economics of reliability.

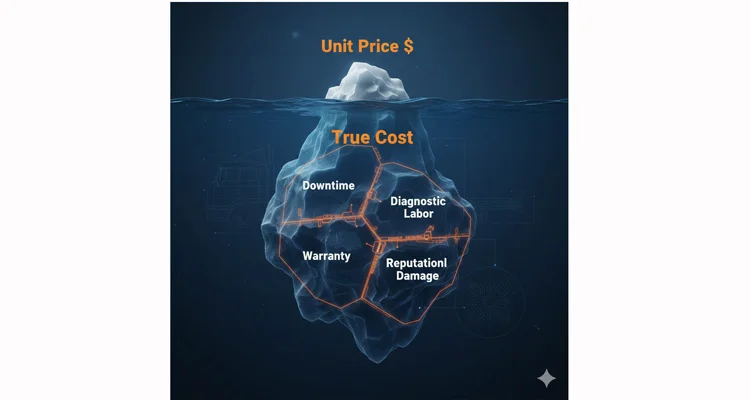

The price on the quote is the down payment. The true cost of a custom cable—paid in technician hours, vehicle downtime, and corrupted data—accrues silently for months. In twenty years, I’ve learned the unit price often represents the smallest part of the final bill. The rest is locked in the decisions made before the first production run.

This is a forensic breakdown of those hidden costs. It’s for the engineer who gets the 8 PM call when a truck won’t communicate, not just the buyer aiming for a quarterly cost target.

The Scenarios Where “Savings” Vanish Overnight

These aren’t theoretical failures. They are Monday-morning problems with a direct line back to a purchase order.

- The Intermittent Fault No One Can Reproduce: A batch of J1939 cables for combines passes all bench tests. Six months into harvest season, operators report sporadic data dropouts. The fault disappears the moment a technician hooks up a diagnostic tool. The culprit is rarely the ECU; it’s often a crimp termination that passed electrical continuity but fails under the specific harmonic vibration of a diesel engine at full load. This micro-movement creates the ghost in the machine.

- The Compliance Crisis: A fleet manager invests in new hardware to ensure ELD compliance. The OBD2 splitter Y-cable chosen was the low-cost option. It works—until a driver connects a handheld scanner simultaneously. The resulting bus conflict corrupts data, leading to an audit failure. The cost of the cable is now irrelevant next to the fines and operational headache.

- The Environment-Specific Failure: A harness for a refrigerated trailer is designed to spec. It functions perfectly in Arizona but fails consistently in Minnesota winters. Condensation forms inside the connector due to a minor sealing flaw in the overmold, leading to corrosion and open circuits. The failure analysis trace, like those we detail in our forensic guide to reefer wiring harness failure, inevitably points to a validation step that was skipped to save on pre-production cost.

In each case, the cable wasn’t “broken.” It was simply not engineered for the totality of its real-world life. The unit price was a false economy, and the real costs—downtime, labor, reputational damage—began accruing immediately.

Deconstructing the Invisible Cost Drivers

When you focus solely on unit price, you pay for material and assembly. You do not pay for the system that prevents the scenarios above. Here’s what the real investment buys.

1. The Sunk Cost of Competence: Tooling & Process Engineering

This is not a line item for a mold. It’s the investment in translating a 2D drawing into a reliable 3D component. It’s the engineering hours to:

- Design a strain relief that absorbs torsion, not just pull, based on the cable’s routing in a truck chassis.

- Source and qualify a specific TPU jacket compound for agricultural machinery that resists not just mud, but glyphosate and fertilizer exposure.

- Engineer the crimp height and terminal insertion process to achieve a gas-tight connection that won’t oxidize, a fundamental part of our IATF 16949 PPAP process.

Skipping this phase to save money guarantees that your cable will be a collection of parts, not an integrated assembly. It’s the difference between a pre-production checkup and walking into production blind.

2. The Insurance Premium: Application-Specific Validation

A custom cable assembly must be validated for your application, not just generic standards.

- Protocol Concurrency Testing: Will your cable handle the electrical load and data integrity when a J1939 network, a J1708 legacy device, and a KWP2000 diagnostic tool talk simultaneously? We test for this because we’ve fixed the failures that occur when you don’t, as covered in our legacy OBD2 protocols guide.

- Environmental Torture Testing: This means temperature cycling from -40°C to 85°C for a northern fleet, or salt spray testing for coastal vehicles. It’s the discipline behind our J1939 cable durability guide for agriculture.

- EMI Immunity Validation: “Shielded” is a meaningless term without a test report. Does the 360-degree shielding maintain continuity through the connector? Does it actually suppress the CAN Bus EMI prevalent in electric forklifts or near high-frequency inverters? Our field guide to CAN Bus EMI shielding explains why this is a systems engineering task, not a checkbox.

Skip this validation and you’re not procuring a cable—you’re buying a box of Schrödinger’s cat scenarios. It works until you observe it in your actual application.

3. The Lifetime Financial Model: Total Cost of Ownership (TCO)

Scrap the iceberg metaphor. Here’s the actual equation:

Visible Cost = Unit Price × Quantity

Real Cost = (Unit Price × Qty) + (Diagnostic Hours × $185/hr) + (Downtime Hours × $750/hr) + (Brand Equity Loss × ?)

That last, unknown variable is where “savings” become existential threats. The TCO includes:

- Cost of Downtime: (Hours to diagnose & replace) x (Hourly revenue loss of the asset). For a $500,000 harvester, this can be hundreds of dollars per hour.

- Cost of Diagnosis: The labor hours spent chasing ghosts, often starting with checking the OBD2 port not communicating, as per our systematic diagnostic guide.

- Cost of Warranty Administration: Processing claims, managing RMAs, and logistical overhead.

- Cost of Brand Erosion: The unquantifiable loss when your reliable product is let down by a cheap cable.

A cable engineered with robust crimp vs. solder choices, validated shielding, and proven durability minimizes this TCO curve from day one. Our shielded vs. unshielded J1939 cable TCO analysis provides the framework.

The Anatomy of a $247,000 “Savings” Mistake

- Months 1-3: “Savings” realized on paper: $8,250.

- Month 4: First field failures appear. Dismissed as “operator error.”

- Month 6: 12% failure rate triggers a production quality hold.

- Month 8: Root cause analysis traces it to cable crimp inconsistency.

- Month 10: Redesign, retooling, and field retrofit complete. Actual cost: $247,000.

The Engineer’s Framework for Total Cost Evaluation

Stop evaluating quotes. Start evaluating partners and their processes.

- Audit the Quality Bedrock, Not the Brochure. Before you send a drawing, request their IATF 16949 certificate and their ISO 14001 environmental management credentials (like our own GB/T 24001-2016 compliance). Ask how 5S management and a climate-controlled warehouse prevent contamination. This is the system that prevents defects. We detailed our journey here: Shenzhen Carsun achieves IATF 16949 certification.

- Co-Design with the Entire Lifecycle in Mind. Share everything: the vibration profile from the vehicle’s chassis data, the chemical exposure list, the expected communication protocol mix. A true partner will ask. This is where you design out problems, like specifying a different OBD2 splitter topology to avoid bus conflicts, informed by our guide on common OBD2 splitter cable problems.

-

Demand and Review the Detailed Validation Plan. “We test it” is not a plan. Request the Design Verification Plan and Report (DVP&R). It must include pass/fail criteria for:

- Signal integrity tests on the actual J1939 connector pinout under load.

- Mechanical shock and vibration profiles relevant to your application.

- Environmental exposure tests (temperature, humidity, fluid immersion).

-

Build a Simple 5-Year TCO Model. With the supplier, use this formula:

Total 5-Year Cost = (Unit Price × Quantity) + (Unit Price × Quantity × Annual Failure Rate × 5) + (Cost per Downtime Hour × Avg. Repair Hours × Quantity × Annual Failure Rate × 5)

Input their unit price, historical field failure rate, your downtime cost, and repair time. The output is your probable total cost. - Establish the Post-Production Support Protocol. What happens after shipment? Do they offer failure analysis support, like our J1939 cable ELD compliance audit failure analysis service? Will they provide diagnostic cable troubleshooting guides? Reliability is a partnership, not a transaction.

The Five Most Expensive Procurement Mistakes

- Prioritizing the Quote over the QMS. Choosing based on a low price PDF, without auditing the Quality Management System (IATF 16949, ISO 9001) that produced it. (A heavy equipment OEM we worked with discovered this cost them over $250,000 in unexpected warranty claims and field service labor in a single year.)

- Accepting Generic “Meets Spec” Validation. Assuming a cable validated to a generic standard will work in your specific protocol soup and physical environment.

- Avoiding Tooling Investment. Pushing for off-the-shelf connector combinations that lead to compromised sealing, strain relief, or shielding continuity.

- The Silo Effect. Allowing procurement to finalize a supplier without the sign-off of the engineering team that understands systematic failure points and reliability requirements.

- Treating the Cable as a Passive Component. It is an active part of the data link layer. A poor cable can make a premium ECU perform unreliably.

How to Recognize a Truly Engineered Solution

You’ll feel the difference throughout the product lifecycle.

During Development

The conversation is technical, collaborative, and challenging. They send you a PPAP package that is exhaustive. Samples don’t just “work”; they survive your in-house abuse tests.

At Production Ramp-Up

First Article Inspection reports match the samples perfectly. Delivery is consistent. There is no “drift” in quality.

In the Field

The cable is forgotten. It doesn’t generate support tickets. When you finally do a post-mortem on a unit after years, the failure mode is predictable and wear-based, not a random, intermittent fault.

Our Philosophy: Delivering Cost-Effective Reliability

Our product lines are the physical outcome of this total-cost philosophy.

For engineers prototyping or diagnosing complex networks, our J1939 9-pin breakout cables are a tool you can trust, built with the same process rigor as a production harness.

For OEMs and large fleets, our range of truck and vehicle cables represents assemblies where every termination, seal, and shield is executed to minimize your long-term operational cost.

Every product is manufactured under a system certified to IATF 16949, ISO 14001, and RoHS/REACH standards, ensuring that reliability is built in, not inspected in.

Frequently Asked Questions (FAQ)

Q1: Is “zero-defect” a realistic claim for cable assemblies?

It is a process target, not a superstition. It means driving defect potential to near-zero through prevention (process control, mistake-proofing, 100% testing of critical parameters) rather than detection (sorting bad parts out). Our IATF 16949 PPAP zero-defect process is the roadmap for this approach.

Q2: We’re under immense time pressure. Won’t this rigorous process slow down our New Product Introduction (NPI)?

A disciplined process accelerates a smooth, scalable NPI. A rushed launch with under-tested cables leads to production stoppages, field recalls, and emergency redesigns—the ultimate project delays. A structured PPAP provides a predictable, reliable path to volume production.

Q3: Can you handle proprietary connectors or obscure vehicle protocols?

This is our specialty. We reverse-engineer communication for manufacturer-specific protocols, design custom overmolds for unique connectors, and build bespoke test fixtures. Bring us the challenge; we will build the solution and the validation plan.

Q4: How do you ensure material consistency, batch after batch?

Through stringent supplier qualification, incoming material inspection against RoHS/REACH standards, and storage in our climate-controlled warehouse to prevent polymer degradation. Consistency is an output of control.

Q5: We’re experiencing field failures with our current cable. Can you help diagnose it?

Yes. Our forensic failure analysis service often starts new partnerships. We deconstruct the failed assembly to identify the root cause—be it a crimp integrity issue, a 3cm fracture zone from flexing, or a shielding flaw—and demonstrate how our process would have prevented it.

Q6: Do you provide engineering support during our system design phase?

Absolutely. Early engagement is the highest-value service we offer. We can advise on connector selection, shielding strategies to prevent EMI, and harness topology to ensure data integrity, helping you avoid costly design flaws.

Q7: How can we verify the authenticity of a supplier’s test reports and data?

Ask for raw data logs, not just summary reports. A credible supplier should provide timestamped test logs from calibrated equipment, evidence of protocol testing against the actual standards (like SAE J1939-21), and traceability back to the specific production lot. We provide full data packages because we have nothing to hide.

Q8: In TCO calculations, what are the most commonly overlooked cost factors?

Two major ones: 1) The cost of diagnostic ambiguity – a faulty cable can mimic an ECU failure, leading to unnecessary, expensive component replacements. 2) Inventory carrying costs – a higher-failure-rate part forces you to stock more spares, tying up capital and warehouse space.

Q9: What’s the first step?

Send us your worst field failure. Our first diagnostic hour is on us. If we can’t identify at least three process control failures in your current supply chain, we’ll tell you to stick with your existing supplier.

If you are evaluating a custom cable assembly and want to understand the full financial and operational picture—far beyond the unit price—let’s have a technical discussion. Bring your schematics, your application challenges, and your cost-of-failure calculations.

Discuss your project with our engineering team or Connect for a direct technical conversation on WhatsApp.

Technical References:

- For definitive information on the J1939 standard, refer to the official SAE International documentation: SAE J1939 Standards. (Note: The SAE standards page may take a moment to load.)

- Details on ISO 9141-2, ISO 14230 (KWP2000), and related vehicle diagnostic protocols can be found in the ISO Road Vehicles — Diagnostic Systems standards catalogue.