Introduction to SAE J1939 Standard

The SAE J1939 protocol represents the backbone of modern heavy-duty vehicle communication systems. Developed by the Society of Automotive Engineers (SAE), this standard has become the universal language for:

- Commercial vehicle diagnostics

- Construction equipment monitoring

- Agricultural machinery data communication

- Marine propulsion systems

- Industrial power generation

At the heart of every J1939 network lies its Deutsch connectors – the critical interface that ensures reliable data transmission in harsh environments.

J1939 Connector Fundamentals

Physical Characteristics

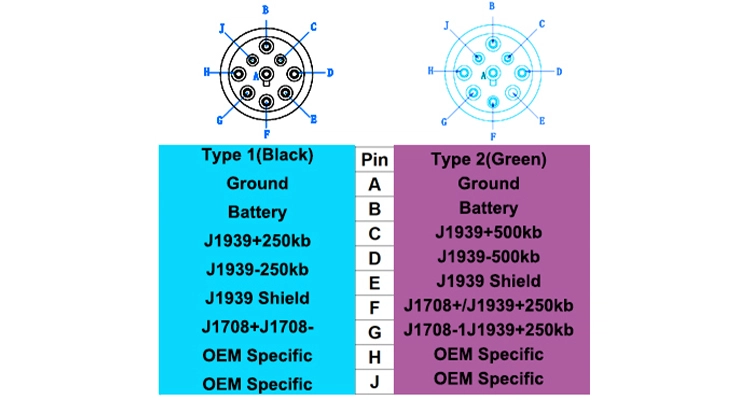

J1939 connectors come in two distinct variants:

| Feature | Type 1 (Black) | Type 2 (Green) |

| Color | Black rubber housing | Green rubber housing |

| Keying | Standard alignment | Offset key position |

| Applications | General purpose | Safety-critical systems |

| Temperature Range | -40°C to 125°C | -40°C to 150°C |

| Vibration Resistance | 10G @ 50Hz | 15G @ 50Hz |

Technical Specifications

Both connector types share these core attributes:

- 9-pin configuration following SAE J1939-13 standard

- IP67-rated waterproof design

- Shielded CAN bus connections (pins 3 & 11)

- 24V DC power capability (pin 8)

- 500kbps data rate (CAN 2.0B compatible)

Key Differences Between Type 1 and Type 2

1. Mechanical Design

Type 1 (Black):

- Straight pin alignment

- Standard latch mechanism

- 50 mating cycle durability

Type 2 (Green):

- 15° offset key position

- Positive-lock secondary latch

- 100+ mating cycle rating

2. Electrical Performance

Type 1:

- 10A current rating

- 250V AC max voltage

- Standard EMI shielding

Type 2:

- 15A current rating

- 600V AC isolation

- Enhanced RFI/EMI protection

3. Application Environments

Type 1 Typical Uses:

- Engine control modules

- Transmission systems

- Chassis monitoring

Type 2 Preferred For:

- Brake-by-wire systems

- Steering control units

- Hybrid/electric vehicle power distribution

Industrial Applications

Heavy-Duty Vehicles

- Real-time monitoring of engine parameters (RPM, temp, pressure)

- Fleet management telematics

- Predictive maintenance systems

Special Equipment

- Construction machinery diagnostics

- Agricultural implement control

- Mining equipment monitoring

Custom Cable Solutions

Our manufacturing capabilities include:

1.J1939 Adapter Cables

- OBDII conversion harnesses

- ECU programming interfaces

- Telematics device connections

2.Specialty Assemblies

- Shielded twisted-pair configurations

- High-flex industrial-grade wiring

- Custom length solutions (0.5m – 10m)

3.Quality Assurance

- 100% continuity testing

- Hi-pot dielectric verification

- Vibration/environmental stress screening

Technical Support

For application engineering assistance:

- Email: linda@obd-cable.com

- Phone: +86-173-0716-8662

- Whatsapp: +86-173-0716-8662

“Our team can help you select the optimal J1939 connector solution for your specific voltage, current, and environmental requirements.”

FAQ Section

Q: Can Type 1 and Type 2 connectors mate together?

A: No – the different key positions prevent cross-mating to ensure system integrity.

Q: What’s the maximum cable length for J1939 networks?

A: 40 meters maximum (at 125kbps) per SAE J1939-14 specification.

Q: Are these connectors compatible with J1962 OBD ports?

A: Not directly – requires an adapter cable with proper pin mapping.

Q: How often should J1939 connectors be inspected?

A: Recommend visual inspection every 500 operating hours in harsh environments.

Conclusion

Understanding the distinction between J1939 connector types ensures proper selection for your application’s:

- Electrical demands

- Environmental challenges

- Safety requirements

- Maintenance considerations

For custom cable solutions or technical consultation, contact our engineering team today.