Introduction: Heavy-Duty Vehicle Diagnostics with J1939 and CAN

Heavy-duty vehicles rely on advanced communication networks to maintain optimal performance, safety, and diagnostic accuracy. Two widely used protocols, J1939 and CAN (Controller Area Network), power these networks. Understanding their differences, real-world applications, and compatibility with vehicle diagnostics tools is crucial for fleet managers, vehicle technicians, and manufacturers aiming to keep trucks, buses, and heavy machinery running smoothly.

External Link: Learn more about CAN: Wikipedia – Controller Area Network

History & Development

The CAN protocol was developed in the 1980s for efficient communication between electronic control units (ECUs) in vehicles. J1939, introduced in the 1990s by SAE, is built on top of CAN and tailored for heavy-duty vehicles, offering extended IDs and standardized messages for engines, transmissions, and other vehicle subsystems. Today, both protocols remain crucial for diagnostics, and future developments are focusing on integration with OBD-II systems and electric vehicle networks.

What is CAN Cable? Features and Applications

CAN (Controller Area Network) is a high-integrity serial bus communication protocol used in automotive and industrial applications. It allows multiple microcontrollers and devices to communicate without a host computer, ensuring real-time system coordination.

Key Features of CAN

- Standardized protocol widely used in cars, light trucks, and industrial machinery

- High reliability with built-in error detection

- Supports real-time communication with low latency

- Flexible for multiple vehicle applications

- Compatible with many diagnostic tools

External Link: More on CAN protocol: SAE International – Standards

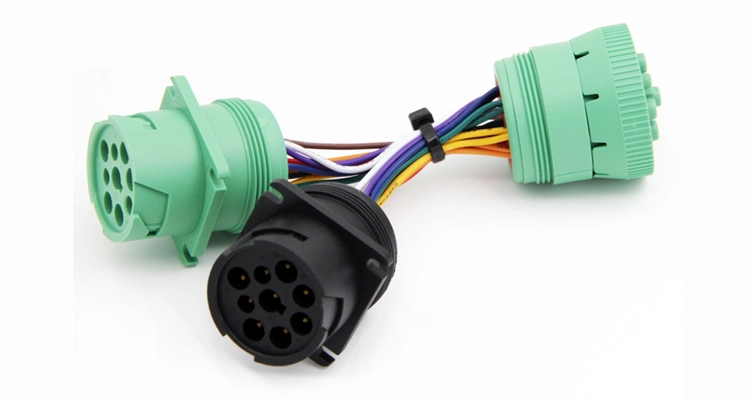

What is J1939 Cable? Features and Applications

J1939 is a higher-level protocol built on top of CAN, primarily designed for heavy-duty vehicles such as trucks, buses, and agricultural machinery. It standardizes messages for engine, transmission, and other critical vehicle subsystems, making communication and diagnostics more efficient.

Internal Link: For J1939 cables, see our Diesel Car Cables and Truck Cables product pages.

Key Features of J1939

- Optimized for heavy-duty vehicles

- Supports extended message IDs and multiple parameter groups

- Allows diagnostic and operational data sharing between ECUs

- Ensures high reliability for long-distance communication in large vehicles

- Compatible with most SAE-compliant trucks and buses

Key Differences Between J1939 and CAN Cables

Compare J1939 and CAN protocols in this table for heavy-duty vehicle diagnostics. Understand the differences in speed, message format, network size, and applications to choose the right diagnostic cable for trucks, buses, and industrial vehicles.

| Feature / Parameter | CAN Protocol | J1939 Protocol |

| Primary Use | Passenger cars, light vehicles, electronics | Heavy-duty trucks, buses, agricultural & construction vehicles |

| Data Rate (Speed) | Up to 1 Mbps | Standard 250 kbps (sometimes 500 kbps) |

| Message ID Format | Standard (11-bit) or Extended (29-bit) | Always 29-bit Extended ID |

| Message Structure | Flexible, less standardized | Strictly defined by SAE standards |

| Network Size | Typically small networks (fewer nodes) | Large networks, supports multiple ECUs across vehicle |

| Interoperability | May vary between manufacturers | Highly standardized across brands for heavy-duty vehicles |

| Diagnostic Use | OBD2 diagnostics for light-duty vehicles | Heavy-duty vehicle diagnostics & fleet management |

| Cable Type | Standard CAN cable | Specialized J1939 diagnostic cable |

| Applications | Cars, motorcycles, small machinery | Trucks, buses, tractors, construction machines |

Tip / Diagram Suggestion

For visual learners, placing a network topology diagram here showing how CAN and J1939 nodes connect can greatly enhance comprehension.

Choosing the Right J1939 or CAN Protocol for Your Vehicle

Light-duty Vehicles

Standard CAN protocol is sufficient for diagnostics and system communication.

Heavy-duty Vehicles

J1939 is recommended for trucks and buses due to extended features and robust communication.

Compatibility

Always verify vehicle specifications to ensure the protocol matches your diagnostic tools and cable types.

Tip: Using the correct cable, such as a J1939 cable, ensures accurate data reading and optimal vehicle performance.

Practical Applications of J1939 and CAN Cables

Fleet Management

Trucks and buses use J1939 to monitor engine health, fuel efficiency, and emissions.

Construction & Agriculture

Heavy machinery relies on J1939 for real-time data sharing between multiple control units

Light Vehicles & Cars

Standard CAN is sufficient for OBD2 diagnostics and general system communication.

Custom Applications

Specialized vehicles may require custom cables for unique ECUs or sensor setups.

How to Choose J1939 and CAN Diagnostic Cables – Tips & Recommendations

Selection Guidelines

- Ensure cable length fits vehicle layout (1.5–5 meters recommended)

- Check connector type compatibility with diagnostic tools

- Verify protocol support (CAN only, J1939 only, or dual-protocol)

- Look for durable, reinforced cables for repeated workshop use

- Consider custom cables for specific vehicle requirements

CTA

Need help choosing the right cable? Talk to Our Experts Now!

Common Questions About J1939 Cable, CAN Cable, and Heavy-Duty Vehicle Diagnostics

Q1: Can I use a CAN cable on a J1939 diagnostic network?

A1: No, J1939 requires extended IDs and specific message formatting; using a standard CAN cable may lead to errors.

Q2: Which heavy-duty vehicles require J1939 cables for diagnostics?

A2: Trucks, buses, heavy-duty construction machinery, and agricultural vehicles.

Q3: How do I choose the right J1939 or CAN diagnostic cable?

A3: Check vehicle protocol, cable length, connector type, and whether the cable supports your vehicle diagnostics tool.

Q4: Can a single vehicle diagnostics tool support both CAN and J1939 protocols?

A4: Yes, some advanced vehicle diagnostics tools are dual-protocol and can communicate with both CAN and J1939 networks.

Q5: What is the difference in communication speed between CAN and J1939 cables?

A5: CAN typically supports up to 1 Mbps, whereas J1939 is optimized for heavy-duty vehicles with a standard speed of 250 Kbps.

Q6: Are J1939 cables standardized for all truck and bus brands?

A6: J1939 is standardized by SAE, but some manufacturers may have proprietary implementations. Always verify cable compatibility.

Q7: How long should a J1939 cable be for reliable diagnostics?

A7: Typically 1.5–5 meters, depending on vehicle layout, to ensure signal integrity and accessibility.

Q8: Can I request custom J1939 or CAN cables for specific vehicle requirements?

A8: Yes, most heavy-duty cables are custom-made. Contact us for professional advice.

Q9: What safety precautions should be followed when using J1939 or CAN cables?

A9: Always turn off the vehicle before connecting or disconnecting cables. Avoid forcing connectors and follow the diagnostic tool’s instructions.

Q10: How do J1939 and CAN protocols relate to OBD2 vehicle diagnostics?

A10: CAN is the underlying protocol for OBD2 in most modern vehicles. J1939 extends CAN for heavy-duty vehicles, ensuring standardized communication.

Contact & CTA for Custom Diagnostic Cables

For custom cables, technical support, or inquiries, our team is ready to assist you. We specialize in custom J1939 and CAN cables tailored to your heavy-duty vehicle needs.

WhatsApp: Chat with Linda

Email / Contact Page: Contact Us

CTA Text Example:

“Looking for a custom J1939 or CAN cable? Contact us today for expert advice and tailored solutions for your heavy-duty vehicles!”