Case Study: Conquering the Dual Challenge of Extreme Vibration & Chemical Corrosion in Forestry Machinery

The Problem: When “Compliant” Doesn’t Mean “Reliable” Last March, a wooden crate arrived at our failure analysis lab, its tarpaulin cover stained with the distinct reddish clay dust from a British Columbia logging site. Inside were seventeen failed wiring harnesses, each tagged with a service log entry. Nestled among the standard ISO 16750-3 certificates and material datasheets […]

Beyond ISO 16750-3: When a Vibration Test Certificate Isn’t a Reliability Guarantee

If you’re overseeing electrical systems for off-road equipment, ISO 16750-3 is a familiar benchmark. It’s the established vibration standard for validating automotive electrical components. However, from our vantage point on the factory floor and failure analysis lab, we observe a recurring, costly contradiction: a perfect lab certificate for ISO 16750-3 filed away, while a physically destroyed harness from the field sits in a warranty return box. The standard […]

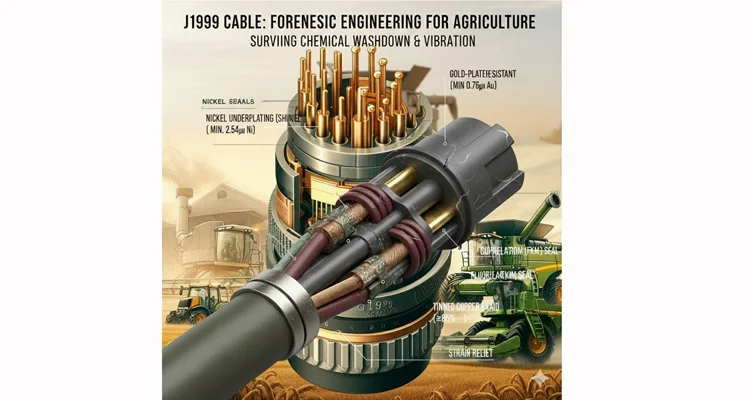

J1939 Cable for Agriculture: Surviving Chemical Washdown & Vibration

When a J1939 cable assembly fails in a modern combine or self-propelled sprayer, it’s rarely a clean break. The failure emerges from two relentless, synergistic forces: low-frequency, high-amplitude vibration that mechanically fatigues every connection point, and a corrosive chemical cocktail that infiltrates every microscopic opening. The symptom is never convenient—it’s the intermittent fault code that appears only at peak operational load, or the […]

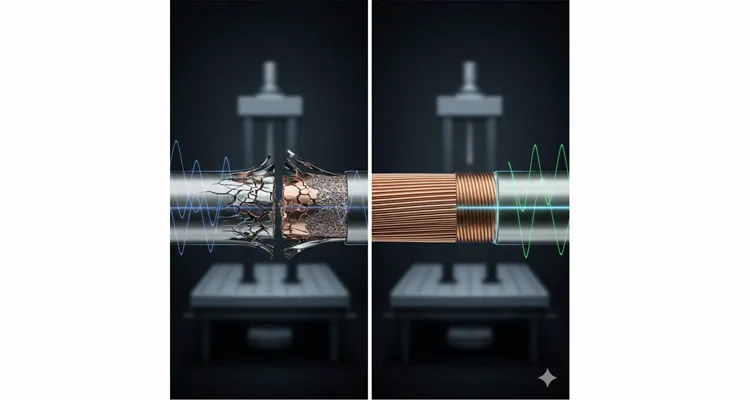

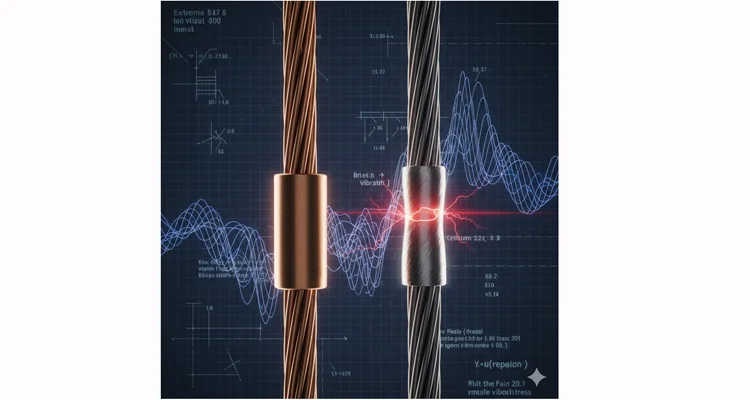

Vibration’s Arbitration: How the “Cold Weld” in a Crimp Decides 40x Longer Life

(Estimated reading time: 14 minutes) Forget the conference room whiteboards. On the failure analysis bench, where we dissect harnesses from harvesters and haul trucks, the solder-versus-crimp debate isn’t theoretical—it’s etched in fractured grain boundaries. This isn’t about preference; it’s a binary outcome dictated by metallurgy. One method engineers a time-bound failure; the other, when executed […]

Crimp vs. Solder: An OEM Engineer’s Guide to Choosing the Right Termination for Vibration Reliability

There’s a moment of quiet realization that comes after the seventh field failure in a fleet of new refrigerated trailers. The diagnostic logs show CAN bus errors only when the compressor kicks in. The waveforms show signal degradation that disappears when the cab is stationary. You’ve checked the protocols, verified the pinouts, even replaced the J1939 connectors. […]

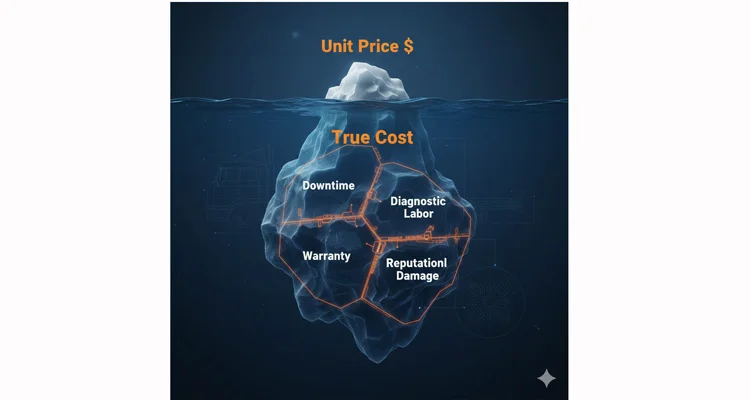

The Custom Cable Quote Is a Lie (Here’s the Real Math)

Three PDFs land in your inbox. Same J1939 connector pinout drawing. Same delivery terms. The only difference? A 27% spread in unit price. Your procurement team’s favorite question—“Why wouldn’t we take the cheapest?”—is about to cost your project six figures in hidden rework. I know because I used to ask that question from the OEM engineering side. Now […]