Beyond the Welder: 5 Less-Obvious EMI Sources Killing Your Heavy Equipment Diagnostics

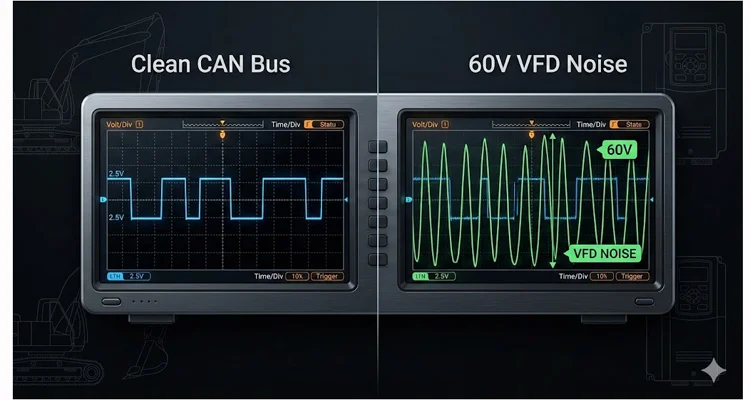

You swap a CAN bus sensor, check the 120Ω terminator, even bypass the suspected wiring harness. The fault—usually something vague like “CAN Bus Off” or “ECU Timing”—clears up for a test drive, only to return as soon as the machine works up a sweat. Everyone blames the welder first. And sure, a guy on night […]

The Welder Kicks On, Your Diagnostic Link Drops Out: Hardening Heavy-Duty OBD2 Systems Against Industrial EMI

The bay is clear. You’re deep into a mandated DPF regeneration trace on a quarter-million-dollar hauler, the data stream inching toward a ghost code that’s cost weeks of downtime. Then—crack-hiss. The adjacent stall’s arc welder fires. Your screen stutters, freezes. “Link Lost.” The cycle aborts. You’ve just burned thirty minutes of labor and triggered a forced regen […]

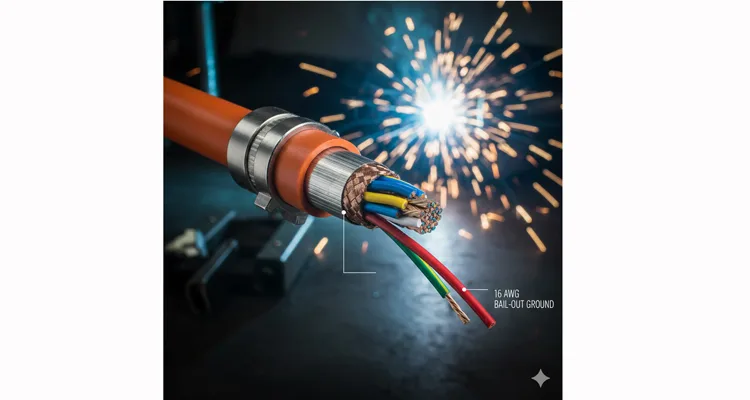

The Ghost in the Machine: How a Simple ELD Installation Can Kill Your Vehicle’s OBD2 Port and How to Prevent It

It wasn’t a faulty ELD unit. The true culprit was your wiring approach. We expose the hidden electrical failures that silently cripple CAN bus networks after installation and detail the OEM-grade hardware installation protocol engineered to prevent them. You’ve installed the Electronic Logging Device (ELD). The driver is ready. The fleet manager is waiting. But the truck’s OBD2 diagnostic port is dead. No communication. No data. […]

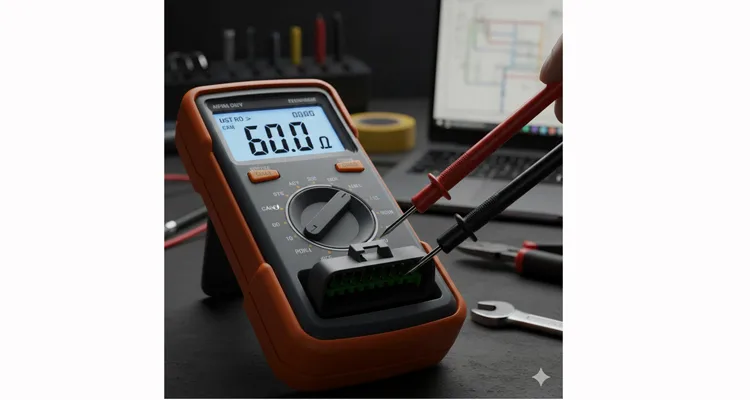

The 120Ω Reading on Pins 6 & 14: The CAN Bus Termination Fault Most Techs Misdiagnose

You know the drill. Communication drops. The dash lights up with a symphony of U-codes, then goes quiet. You grab your multimeter and probe the OBD-II port—Pin 6 to Pin 14. It reads 120Ω. “That seems fine,” you think. It’s a 120-ohm bus, right? Then it clicks: that’s the value of one resistor, not the network. Your CAN bus is running […]

The CAN Bus Health Check: What Your Multimeter is Really Telling You (And What 60Ω, 120Ω, and 0Ω Actually Mean)

Your multimeter gives you a number. This table translates it into your first actionable clue—before you even open a wiring diagram. Reading (Powered Off) Likely Diagnosis Next Action 0Ω – 5Ω Hard Short Physical hunt for pinched wires or water ingress. Use the Split-Half Method to isolate. ~40Ω Over-Termination Find and remove the extra 120Ω load (e.g., […]

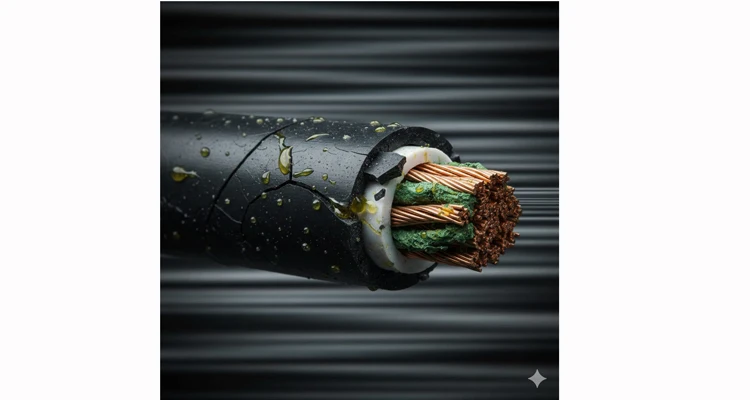

The Diagnostic Puzzle: Why Your “Vibration-Rated” Cable Fails in Corrosive Environments

Two years ago, a diagnostic case landed in our lab: a bundle of wiring harnesses pulled from fertilizer spreaders, all failing with intermittent CAN bus faults. The OEM’s records pointed to an ISO 16750-3 vibration certificate from their supplier. Yet, the physical evidence—cracked jackets, brittle insulation, and copper conductors tinged green—told a different story. The certificate wasn’t […]